Benefits to Using Shadow Boards in a 5S Workspace

Written by Adam Serfas

Benefits to Using Shadow Boards in a 5S Workspace

The 5S System has long been a guide processors have followed to streamline their facilities. Originally developed in Japan by Toyota, the 5S system relies on 5 major components or phases that should be considered as a framework for improving processes in a production line: sort, set in order, shine, standardize, and sustain. Below we’ll explore how implementing shadow boards in your facility can help to achieve each of these goals. At R.S. Quality Products, we strongly recommend that every client that implements a color-coding plan install shadow boards in their facility.

To view this content as a printable pdf click here.

1. Sort

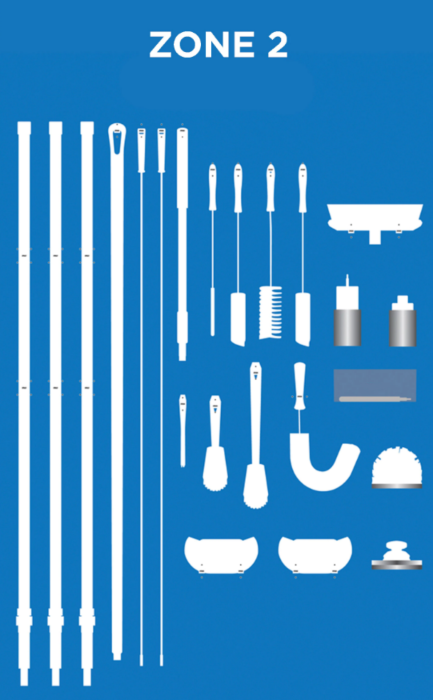

Though shadow boards are generally custom-designed and can be made from a variety of materials, they all exist primarily to organize the tools in your facility and give them a designated home. Planning a shadow board requires sorting or taking stock of the tools used on a regular basis in your facility, a good practice to ensure you clear clutter from your facility.

2. Set In Order

Out of all of the 5S phases, this one is clearly demonstrated and achieved by the use of shadow boards. A shadow board, of course, exists to clearly identify regularly used tools and their appropriate storage place. These help employees to readily identify any missing tools - which can be extremely important in spaces like food and drug manufacturing facilities where a missing tool can be a potential contamination risk. In addition to organizing your tool storage areas, this practice also helps to organize the facility itself as it is recommended that shadow boards are placed in areas in close proximity to their associated workstations.

3. Shine

This phase, which refers to a clean and organized workspace, is best achieved when a shadow board is well thought through. It’s important that the shadow board is designed to include only the vital tools, is clearly labeled and colored, and is positioned in the appropriate area of your facility. When this is done correctly, your workspace will remain tidy and perhaps even shine.

4. Standardize

Shadow boards help standardize your entire color-coding plan making it easy for any worker to hop in at any station and understand the color-coding plan, and know what tools go where even if they aren’t familiar with that station or its tools.

5. Sustain

This final phase is vital to ensuring the success of your facility’s color-coding plan. Fortunately, a shadow board can hope to ensure sustainability. Tools are better taken care of because they have a designated storage area, workspaces stay tidier and employees can work more efficiently without the need to search for tools. At a quick glance, shadow boards offer confirmation of a color-coding plan being followed correctly, and most importantly, the ability to readily identify missing tools actually allows for a safer environment.

Shadow boards are the best solution to creating a visual system for your tools and, when done correctly, can help you to meet 5S criteria in your facility. For questions on how best to create your shadow board, contact R.S. Quality to discuss your unique needs.