Color-Coding

Implementing color-coded cleaning plans in food-safe and hygiene-sensitive environments offers many benefits, above all helping to ensure quality and safety in a facility. For a color-coding plan to be successful, the planning process must be approached thoughtfully.

Here at RSQP, we offer our customers guidance on color-coded cleaning and encourage reaching out for assistance on everything from drawing up a plan from scratch or revising an existing one. We’ve also created this page to serve as a resource for all things color-coded cleaning and an introduction to the most commonly used plans.

COLOR-CODED CLEANING PLAN DEFINITION:

A strategy for a food-safe or hygiene sensitive facility that designates certain colors for a specific area or purpose, designed to promote safety and cleanliness.

INDUSTRIES THAT BENEFIT FROM COLOR-CODING:

- Food Manufacturing & Processing

- Meat & Seafood Processing

- Pharmaceutical Manufacturing

- Brewing

- Healthcare

REASONS TO COLOR-CODE:

- Ensures longevity and proper handling of tools

- Helps meet FDA and HAACP requirements

- Reduces pathogen and allergen contamination

- Promotes a hygiene-focused culture

- Helps with long-term money saving

EXAMPLE COLOR-CODING PLANS

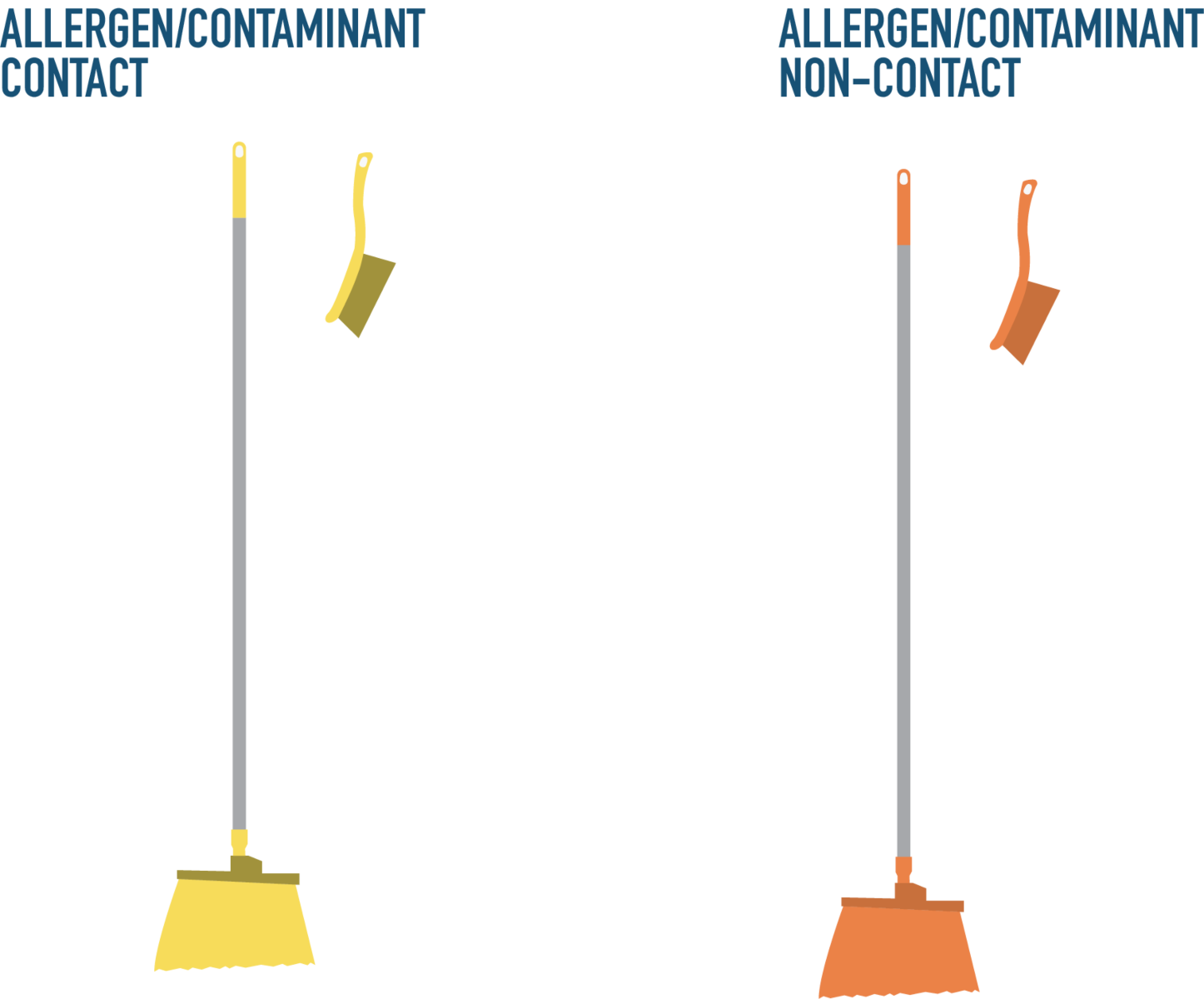

ALLERGEN/POTENTIAL CONTAMINANT DISTINCTION

Facilities that handle common allergens are at a higher risk for contamination issues. Most commonly, this pertains to food manufacturing and processing, brewing and pharmaceutical manufacturing. Here, those affected would assign a special color to tools that come into contact with the allergen. To learn more, visit our full guide on color-coding by allergen here.

Additionally, any plant that handles both chemicals and food product would want to similarly assign a color for tools used with chemicals as they present a high contamination risk.

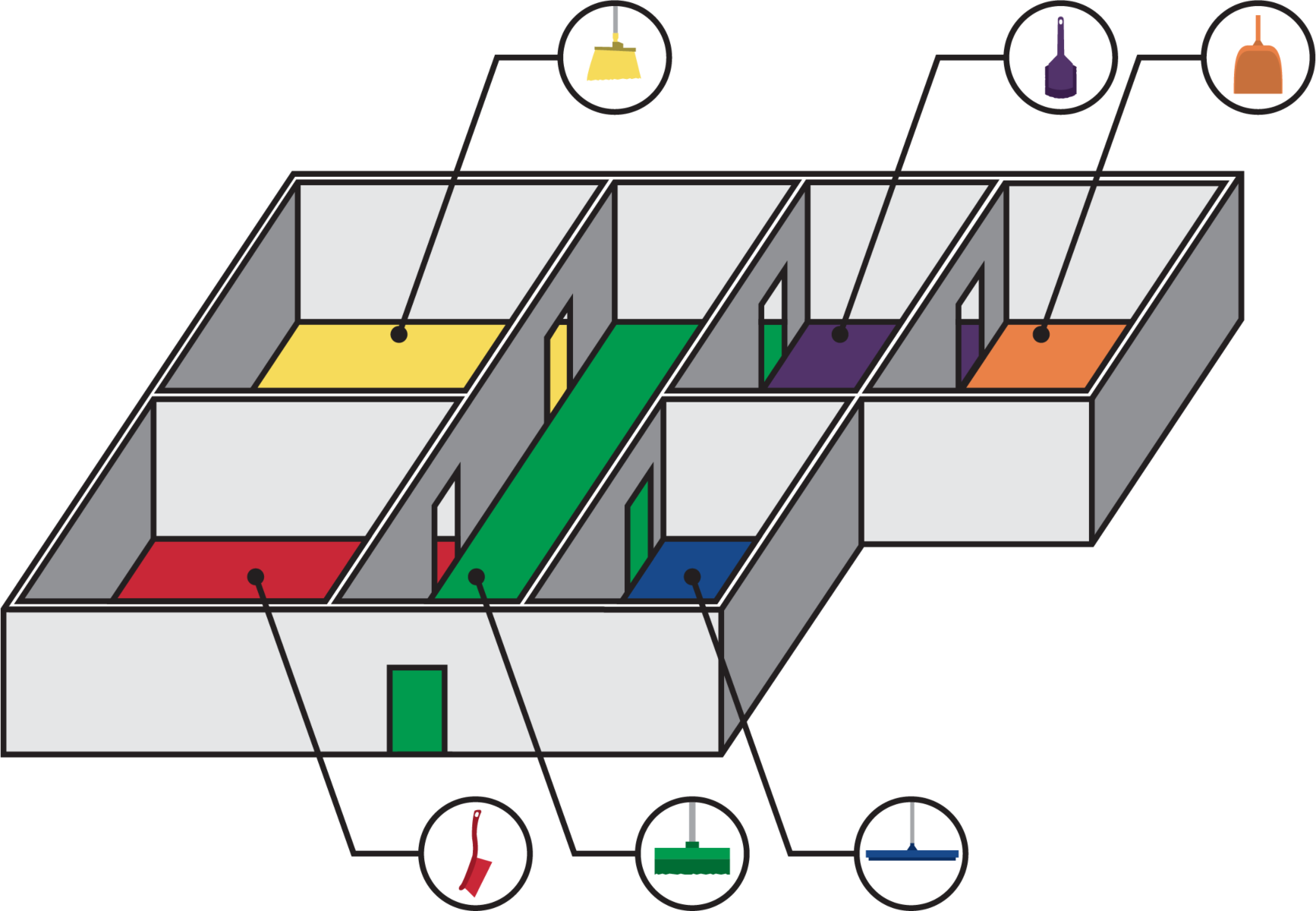

Learn MoreZONE DISTINCTION

Many larger facilities, particularly manufacturing facilities, are built with designated areas or zones sectioned by step in the production process or by product. For that reason, it’s popular to designate colors to zones to differentiate tools and cleaning supplies that belong to each area. This can help with everything from prevention of contamination between zones and ensure proper organization and storage of tools by holding each zone accountable.

Similarly, healthcare centers often color-code by floors or wings.

Learn More

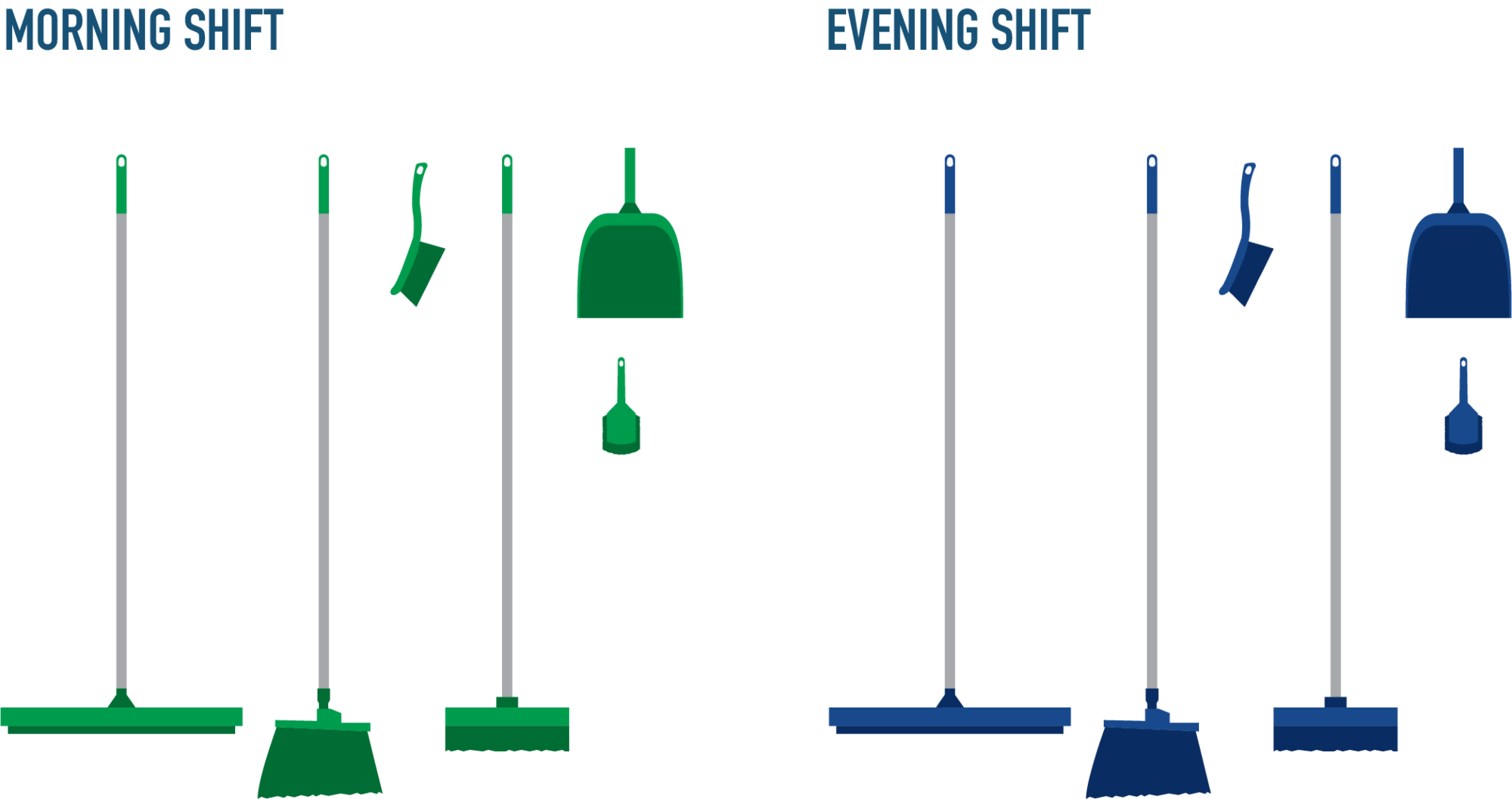

Shift Distinction

Employing a large staff sometimes makes it difficult to hold people accountable on tool care and cleanup duties. It is a common practice to assign colors to shifts to tackle both of these problems. Additionally, for wet cleaning facilities, this allows drying time for cleaning tools between shifts.

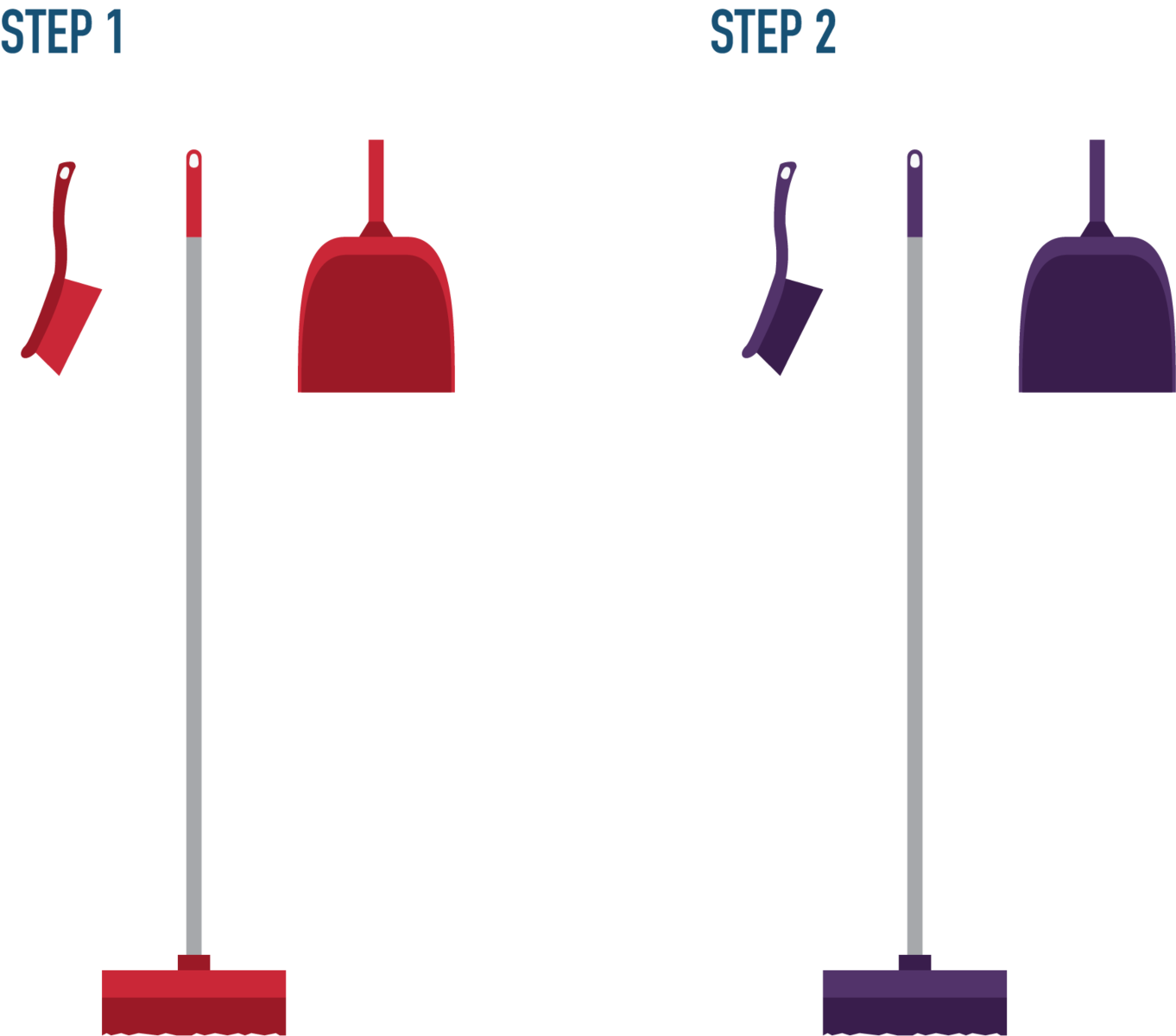

Learn MoreAssembly Process Distinction

Facilities that have any type of assembly process in place often look to color-code by assembly process. This is especially important in food manufacturing and processing plants, where these steps need to be kept separate.

One common example of this method in practice can be seen in meat processing facilities and kitchens where colors designate tools and utensils for raw and cooked meat.

Learn More

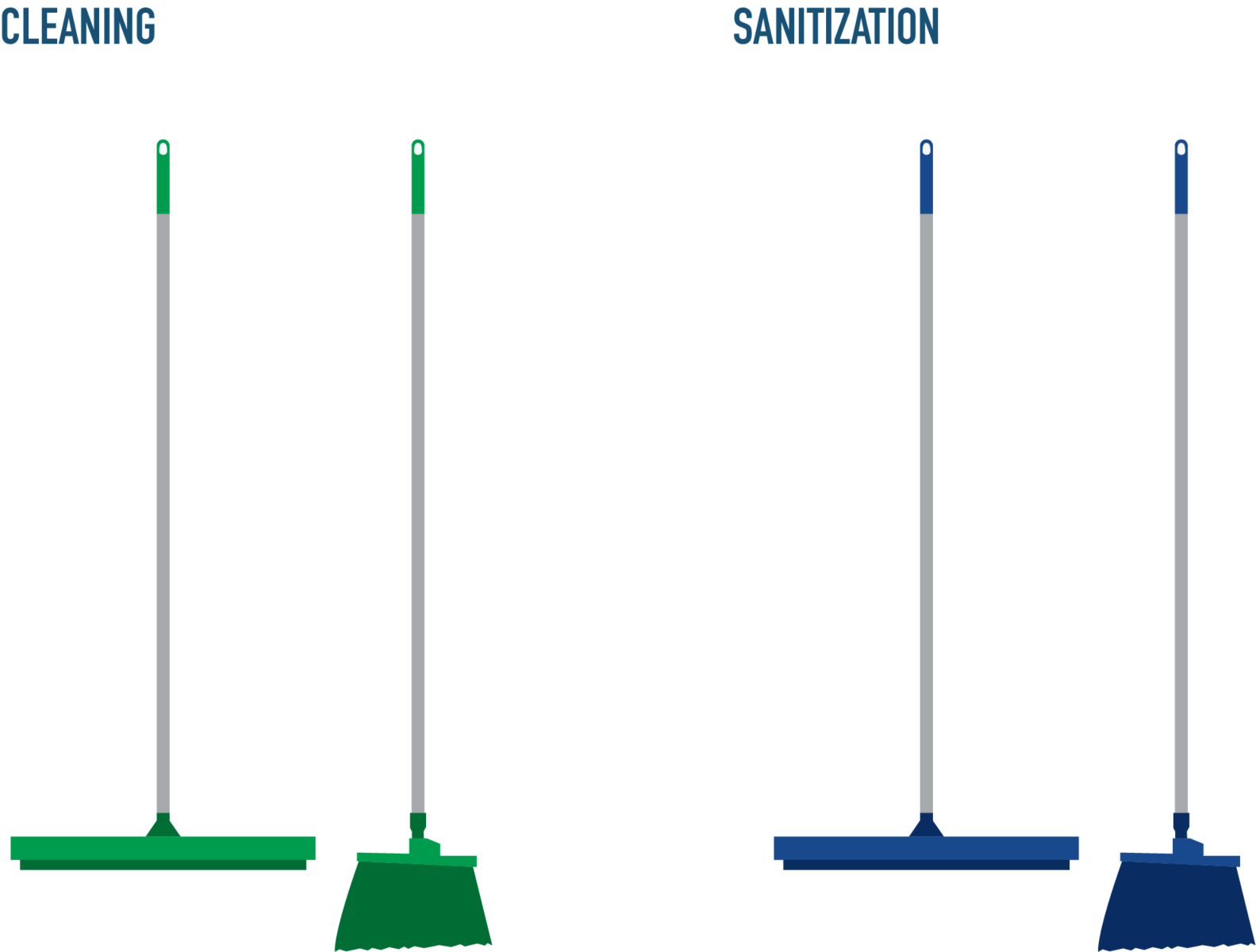

Cleaning Purpose Distinction

For many facilities, there is a clear distinction between cleaning and sanitation procedures. Those concerned with upholding these high cleanliness standards often choose to implement two-color plans to distinguish tools for cleaning and sanitation.

Learn More